STEAMPOWER

Protection and Monitoring from ParkerMeggitt,

delivered by the swedish system integrator Rotatic Sweden AB

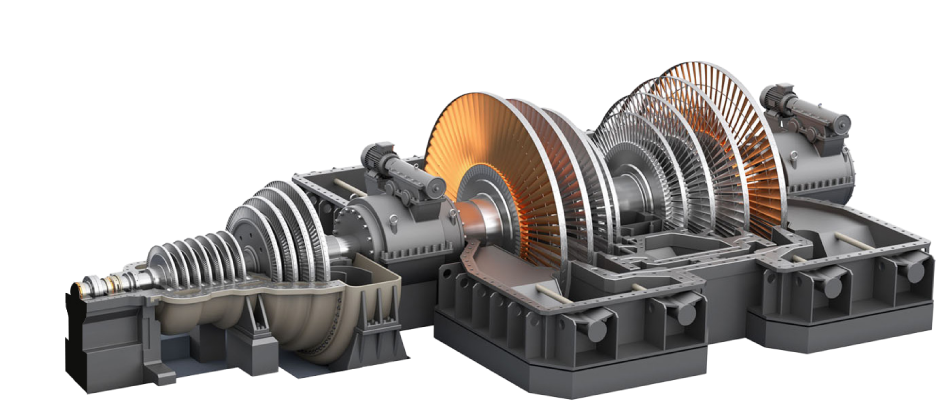

Steam turbines are important for the swedish energy production

Besides the stable base power the steam turbines deliver, are there many back-pressure turbines also delivering steam of the correct pressure for the process industry. Many reasons makes it important to secure operations and keep a good control of this equipment. With modern quality system it is possible to detect discrepancies earlier and achieve the best safety with the highest return of investment.

Vibro-Meter/Meggitt has been in the forefront in this industry, with more than 10 000 installed VM600 vibration racks and over 100 000 installed measurement chains for relative vibration.

These units are used as both machine protection, with SIL-classification if needed, and for monitoring, vibration, trending etc; coupled with the first class softwareVibrosight.

Rotatic Sweden AB is the swedish system integrator and distributor for Vibro-Meter/Meggitt. We can help you through the whole process - from product selection to startup, and after that service and support - all according to your needs.

Read more about VM600Mk2 here (Meggitt website)

Read more about Vibrosmart here (Meggitt website)

Get inspired by Advanced Condition Monitoring and Protection for Chritical Rotatic Machinery (pdf)

and Steam Turbine Monitoring – An introduction (Article)

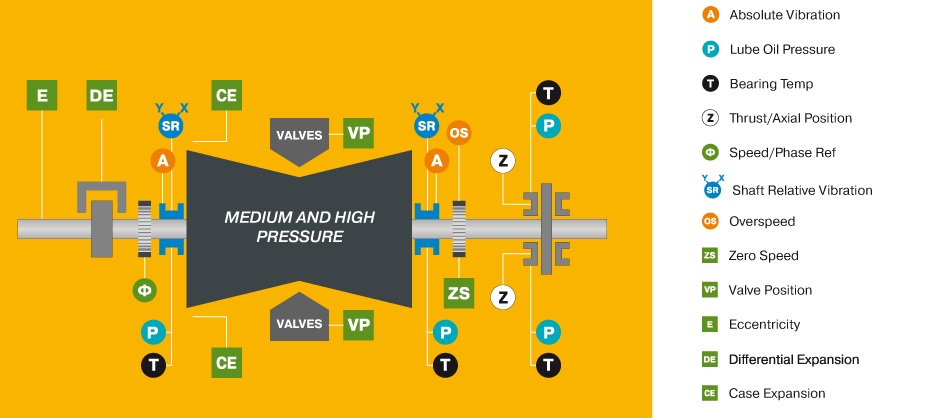

Machine protection and monitoring

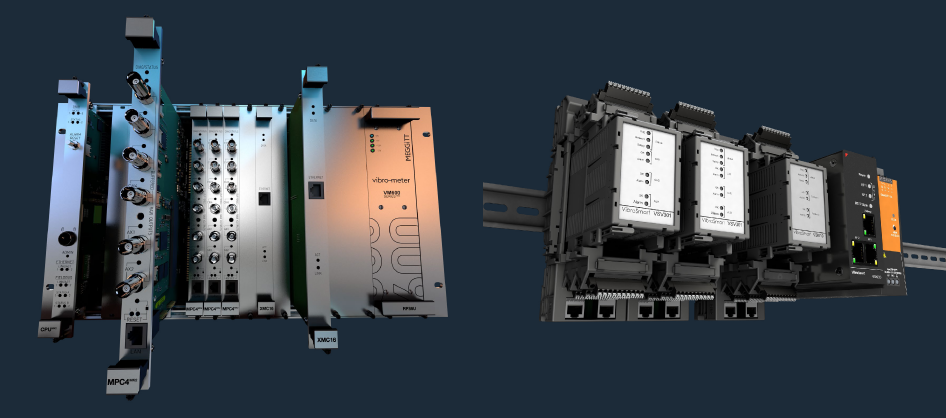

It's ment to be easy and reliable to protect people and equipment, no matter the pre-conditions. We deliver both centralised (VM600 Mk2) and distributed systems (VibroSmart), where both alternatives provide for fewer spare parts on stock and user friendly interfaces to make the ownership more convenient.

The MPC4-card were the first on the market to deviate from application specific module cards and instead offer one-card-does-it-all. With 4 dynamic- och 2 aux channels (Tachometer and DC) for in signals, 4 configurable relays, 1 status relay and 4 analog output signals (configurable for 4-20mV or 0-10V), the card covers a wide area. Connect accerelometers, speed sensors, proximity probes, piezoelektric sensors for tacho, vibration, axial position, absolute and relative vibrations, dynamic pressure, air gap sensors, RPM... and more. With the Mk2-version the cards can also be hot-swapped; the configuration of each cards is stored in all the other installed cards for redundancy and easy restoration at replacement - making service easy and conventient.

The architecture in VM600 Mk2 is designd for separate machine protection and montitoring, making physical access a requirement to modify the configuration, while at the same time making central monitoring easy to access via t.ex. MODBUS eller OPC. The Vibrosight software offers komplex analysis of events comprehensible and easy; by time-syncronising data from other available sources in the control system, an event becomes detailed and comprehensible in one interface. Vibrationsexperts are able to extact data to analyse events.

VibroSmart is a distributed system with the cost of cabling in mind; if there aren't existing, usable, cables between machine and rack large saving can be made. By using modules placed near the machine, ethernet cables can be used for the long distances - providing savings both financial and in terms on complexity. VibroSmart is also beneficial to use when having few sensors for equipment with a smaller footprint. E.g. smaller size critical equipment such as water feed pumps, compressors, fans and similar. With VibroSight software, the data from VibroSmart can be processed and analysed in the same manner as for the centralised VM600-units.

Both systems are compadible with sensors from other brands, making it possible to divide the systems upgrades in stages, making the budget planning a bit easier.

Read more about VM600Mk2 here (Meggitt website)

Read more about Vibrosmart here (Meggitt website)

Be inspired by A Practical Guide for understanding Turbo Supervisory Instrumentation (pdf)

Sensors for Steam turbine applications

vibro-meter’s full range of vibration, displacement and rotor motion sensors can be used with our monitoring system hardware and software, or third-party systems, to provide complete solutions for the monitoring and protection of steam turbines and processes. From standard to industrial environments, including hazardous areas and/or extreme temperatures

For best overview of the portfolio, please see: Sensors and Measurement chains for turbomachinery (pdf)

Examples above:

Moving-Coil Velocity Sensors - Our CV21x and VE210moving-coil velocity sensors have the advantages of being self-powered and providing a strong output signal in native velocity units (mm/s), so the signal- to-noise ratio is excellent, and no integration is required.

Accelerometers with External Electronics - The CA The CA series of sensors are high-temperature, piezoelectric-based accelerometers designed for the long-term measurement and monitoring of absolute vibration in the most severe of environments (up to 700°C).

Accelerometers with Integrated Electronics - The CE series of sensors are piezoelectric-based accelerometers that come with either attached electronics for higher temperature applications (up to 350°C) or integrated electronics for lower temperature applications (up to 120°C). These sensors are suitable for the vibration monitoring in steam turbines, compressors, pumps, and fans.

Proximity probes - The TQ series covers a broad measurement range from 2 to 12 mm and are designed to withstand pressures up to 100 bar from speed and vibration to large-displacement expansion measurement using pendulum probes.

Housing Expansion LVDTs - The AE119 housing expansion probes use LVDTs for the measurement of casing expansion on the high-pressure end/side of large steam turbines.

Data sheets and possible conficuration of each procut may be found at the Parker Meggitt wesite: Sensors & signal conditioners (Meggitt website)

Userfriendly software

The VibroSight software impresses with its userfriendly and effiecient interface, scalable and easy to configure - with high security. It is a very capable software for data analysis and visualisation.

The VibroSight modules consists of Protect, Capture, Configurator, Event Viewer, Mimic, Vision, System Manager och Server - Further more there is also Diagnostic Rulebox available, a powerful module with diagnosic rules capable to detect discrepancies based on multiple sources, and can by that indicate possible issues before normal single source levels are reached.

VibroSight can be configured to store detailed data before a trip-event - by keeping a high resolution data buffer, which normally is thinned out, a trip can trigger the high resolution buffer to be stored. That way a deep and detailed analysis can be made to see what actually happened before the trip-event. Historical data can easily be configured to be cleared out after a pre-defined time, this to avoid storage to be full and available for current data.

Läs mer om de olika modulerna här: Vibrosight (Meggitt hemsida)

Well established in the world

The Parker Meggit systems are well established around the globe after being on the technical forefront for over 70years. Since 2001 there has been over 10 000st Vibro-Meter VM600 machine protection systems delivered globally; Amongst other, Hydro power, Nuclear power, Process industry, Steam power, Gas power and Offshore.

VM600 are used for protection and monitoring of turbines, compressors, generators and other rotating equipment within different industries and sectors.

Upgrade of older systems

If you have an older system that needs upgrading, solutions can be tailored for phased implementation. If the older sensors are functional and reliable, you can initially upgrade to VM600 Mk2 or VibroSmart with some additional sensors that may be missing in the existing configuration. Meggitt’s systems are fully compatible with sensors from other manufacturers, such as Bently Nevada and CTC, as you can easily define the input signals in the system; this way, you can spread out investments during a larger system upgrade.

If you rely on mechanical overspeed systems or older electrical ones, it may be appropriate to review safety measures. Feel free to be inspired by this brochure: The Speedometer Guide (pdf)

Additionally, this article is recommended: 8 Insights – What customers told us about Vibration Monitoring Upgrade Project (Article)

Tjänster och möjligheter

Rotatic is not just a system integrator for Parker-Meggitt; we work with most types of rotating equipment in the form of service, maintenance, overhauls, and staffing.

We are happy to handle rewinding, reverse engineering, commissioning, and other tasks related to rotating equipment - both electrical and mechanical.

An overview can be seen at: rotatic.se

Maintenance 4.0

With the help of quality sensors, extensive data collection and coordination, Rulebox, and complex multifactor analyses, maintenance can be taken to the next level.

The concept of Maintenance 4.0 is about anticipating and forecasting maintenance needs; however, it also requires information about the equipment in a qualitative and reliable manner.

The first step is to invest in data collection and processing, and the next step is making decisions.

Separate overspeed protection

Overspeed can have catastrophic consequences, posing risks to both people and property. The best way to protect against this is through an independent and redundant system with lightning-fast response time.

The Vibrometer ODS301 (Overspeed Detection System) can be configured according to needs, with the same units used to scale up SIL and redundancy; depending on the requirements, 1-3 units can be used.

Read more about overspeed protection in this brochure: The Speedometer Guide (pdf)